Welcome To

COMPANY PROFILE

"Ankur Traders and Manufacturers" is a Lucknow-based stainless steel fabrication company established in 1992. Ankur Traders, under the brand name "Goyal Arc" has fully blossomed into one of UP's leading fabricators and supplier of S.S. Railing, S.S. Bus Shelter, S.S. Bollards, S.S. Plates, S.S. Barricades, S.S. Water Sink, S.S. Fire Doors, S.S. Dustbins & benches, S.S. Dome , S.S. Signages, S.S. & M.S. Industrial motorized gates & front building CNC Elevation.

"Led by the vision of its founder, Mr. Ankur Agarwal, and the dynamic direction of his brother, Mr. Anupam Agarwal, Ankur Traders excels in progress, focusing on customer satisfaction".

We are a globally recognized ISO 9001:2008 certified company specializing in the manufacturing, trading, and supplying of high-quality stainless steel products. Our range includes railings, balusters, furniture, and bathroom accessories, all designed to be both functional and aesthetically pleasing.

Infrastructure

Factory: Our factory located at Dubagga is equipped with cutting-edge technology and machinery, enabling us to maintain high standards of quality and efficiency.

Advanced Manufacturing Plant: Our plant on Kursi Road is designed to handle large-scale production with precision and speed, ensuring timely delivery of our products.

Strategic Head Office:Our head office in Nirala Nagar serves as the nerve center of our operations, housing our leadership team, and supporting functions.

Manpower

Skilled Workforce:We take pride in our team of over 600 skilled professionals who bring their expertise and dedication to work every day, driving our success.

Experienced Team: Our team members have extensive experience in their respective fields, ensuring that we maintain the highest standards of quality and innovation.

PRODUCTION

PRODUCTION LINE

Pipe Cutting Stage

The stainless steel pipes are selected based on the required specifications such as diameter, thickness, and length. Then, the pipes are cut to the desired length using specialized cutting tools. After that, the ends of the pipes are prepared for welding by chamfering or beveling.

BAND SAW CUTTING MACHINE

POWER - 1.512 KW

CAPABILITY -Bevelling pipes of any thickness and diameters.

LATHE MACHINE

POWER - 1.5 KW

CAPABILITY -sawing, cutting, boring holes, sanding, knurling and drilling jobs.

WELDING STAGE

TIG (TUNGSTEN INERT GAS) WELDING

POWER - 2.5 KW

(It offers precise control and produces high-quality welds with minimal spatter.TIG welding is favored for its precision, cleanliness, and ability to create strong, aesthetically pleasing welds).

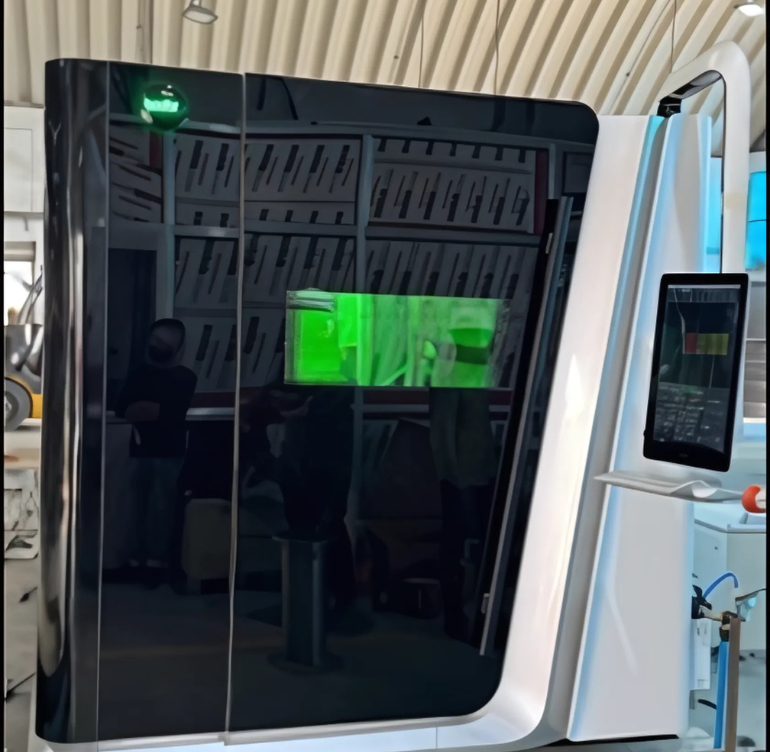

LASER WELDING

POWER - 7.5 KW

(Laser welding is a welding technique that uses a highly focused laser beam to join materials together.It offers several advantages, such as high precision, minimal distortion, and the ability to weld complex shapes).

GRINDING & POLISHING STAGE

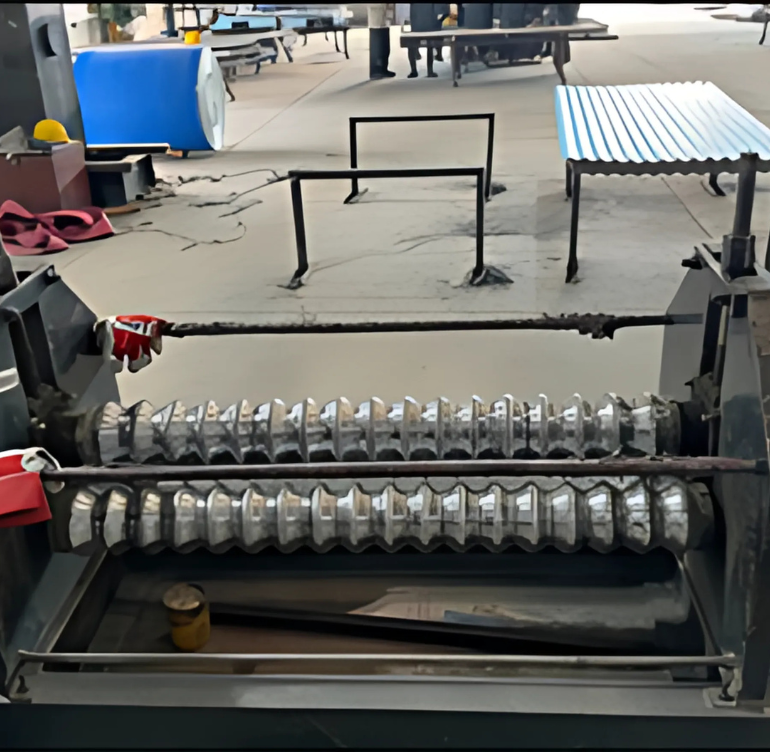

LANCER MACHINE

POWER - 5 KW

CAPABILITY - grinding & polishing of metal, iron rod, and as well as aluminium profile.

POLISH ADDA MACHINE

POWER - 5 KW

CAPABILITY - grinding & polishing of metal, iron rod, and as well as aluminium profile.

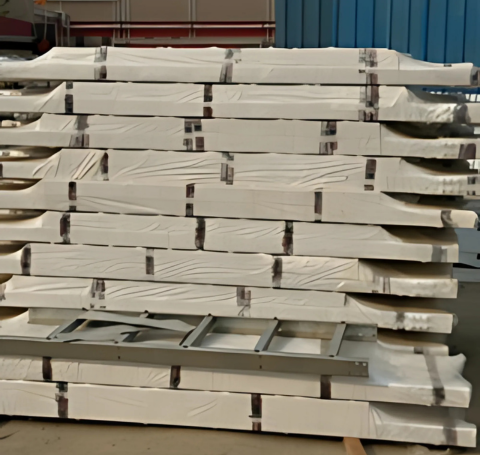

PACKING & LOADING STAGE

Packaging Solutions:

Our firm offers a wide range of packaging options to ensure the safe delivery of your products. From custom boxes to protective materials like bubble wrap and foam inserts

FORKLIFT

CAPACITY - 70,000 lbs

QUALITY CHECK & SAFETY STAGE

When it comes to quality checks for stainless steel pillar production, here are some key checkpoints we consider:

At our firm, the safety and well-being of our employees and consumers are at the forefront of our operational values. Recognizing that safety is integral to fostering a productive and secure work environment, we have instituted comprehensive safety protocols that adhere to industry standards and regulatory requirements. Every employee undergoes rigorous training to ensure they are knowledgeable in best practices for maintaining safety across all activities. This training covers not only routine tasks but also emergency response procedures, promoting a culture of vigilance and readiness.

One of our core measures includes the consistent use of personal protective equipment (PPE). We equip our team with high-quality PPE suited to their specific roles, whether they work on the front lines of manufacturing, construction.

MACHINES

MACHINES

MACHINES

Hello! I’m Ankur Agarwal

100 +

100 %

200 +

Why Choose Us

Why choose us

Durability

Low maintenance

Modern aesthetic

Customization

Eco-friendly

Steel Gates and Doors

Award & achievement

ISO 13485:2016

Authorized dealer

Indian Food Expo-22

UP Powering New India

Oral

Steps

How organization works

Process

Skilled Team

Quality Assurance

Advanced Infrastructure

Smooth delivery

Client feedback

Hear from clients.

Clients

Our Client

Gallery

Our Gallery